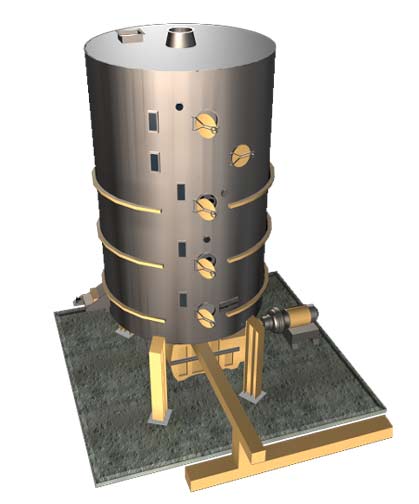

After the oil has been removed from the flakes or cake, they leave the Crown Extractor with approximately 30% solvent (hexane) content. The Crown/Schumacher DT is the newest innovation in removing the hexane from the flakes and completing the toasting operation. After the oil has been removed from the flakes or cake, they leave the Crown Extractor with approximately 30% solvent (hexane) content. The Crown/Schumacher DT is the newest innovation in removing the hexane from the flakes and completing the toasting operation.

The solvent laden flakes enter the top and land on the predesolventizing tray, which is steam heated. The flakes are evenly distributed onto the first main tray.

Each main tray has hollow stay bolts for venting vapours from one tray to the next. The quantity and position are carefully designed to allow maximum contact between vapours and meal.

Steam is injected through the perforated bottom tray. The steam strips the final solvent from the meal and then vents up through all the trays above. A true counter current desolventization is achieved, previously unavailable in DT’s. The result is a uniquely low solvent content in desolventized meal, and significantly reduced solvent losses.

The meal flows from one tray to the next through chutes. The bottom tray contains a specially designed variable speed rotary valve to maintain a level.

The combination of the steam heated trays and counter-current steam stripping raises the meal temperatures faster and slightly higher than conventional DT’s. Temperatures are more stable in lower trays and provide for a greater degree of safety.

Equipment Brochure

|